Motor Failure and Troubleshooting

Table Of Contents

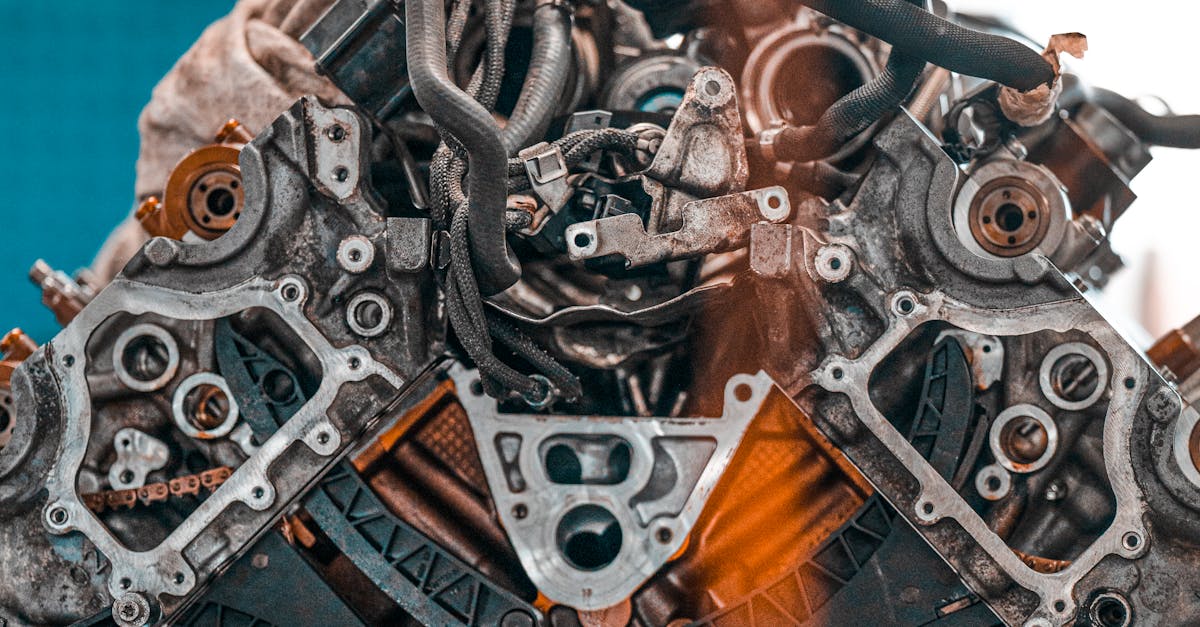

Evaluating the Motor's Performance

Evaluating the motor's performance is a crucial step in ensuring the efficient operation of any machinery or vehicle. Begin by observing the motor's operation during regular use and take note of any abnormal sounds or odours emitted during performance. Additionally, monitor the motor's power output and speed to determine if it is operating at its designed capacity.

Furthermore, conduct visual inspections to check for any signs of wear and tear on the motor components. Look for loose connections, overheating, or unusual vibrations that could indicate potential issues. By evaluating these performance indicators regularly, you can identify any potential problems early on and take the necessary steps to prevent costly motor failures.

Discover more here.

Testing for Vibrations

Vibrations in a motor can indicate underlying issues that need to be addressed promptly. Excessive vibrations can lead to further damage if not resolved in a timely manner. When testing for vibrations in a motor, it is essential to first visually inspect the motor while it is running to identify any noticeable shaking or movement that is not typical.

Additionally, using a vibration meter can provide more accurate measurements of the motor's vibrations. By attaching the vibration meter to different parts of the motor, such as the housing or the shaft, you can pinpoint the source of the vibrations. It is important to compare the readings obtained with the manufacturer's specifications to determine if the motor's vibrations are within acceptable limits. If vibrations are exceeding the recommended levels, further investigation and potential maintenance may be required to prevent motor failure.

Troubleshooting Starting Difficulties

When faced with starting difficulties in a motor, the first component to examine is the starter motor itself. Begin by checking the connections to ensure they are tight, secure, and free from corrosion. Loose or corroded connections can hinder the flow of electricity needed to start the motor, leading to difficulties in starting. If the connections appear to be in good condition, the next step is to assess the condition of the ignition switch. A faulty switch could prevent the motor from receiving the necessary signal to start.

If the connections and ignition switch check out, the next area to investigate is the battery. Start by inspecting the battery terminals for corrosion or build-up that may be impeding the flow of electricity. It is also essential to test the battery's voltage to ensure it is within the correct range for starting the motor. A low voltage reading could indicate a weak or failing battery that needs to be replaced to resolve the starting issue.

Examining the Starter Motor

The starter motor plays a crucial role in the overall functionality of the vehicle. When examining the starter motor, it is important to first visually inspect the motor for any signs of corrosion or damage. Check the wiring connections to ensure they are secure and free from any wear or tear that may impede the motor's operation.

Next, test the starter motor using a multimeter to measure the electrical current it is receiving. This will help determine if the motor is getting the power it needs to function properly. If the starter motor is not receiving the correct amount of power, it may need to be replaced or repaired to avoid further issues with starting the vehicle. Regular maintenance and inspection of the starter motor can help prevent unexpected failures and ensure the smooth operation of the vehicle.

Preventative Maintenance Tips

To ensure the longevity and optimal performance of your motor, regular inspections are essential. Make it a habit to inspect the motor for any signs of wear and tear, such as frayed wires or loose connections. Addressing these issues promptly can prevent more significant problems down the line. Additionally, keep the motor clean and free from dust and debris by regularly cleaning the exterior surfaces with a soft cloth.

Another crucial preventative maintenance tip is to lubricate moving parts regularly. Check the manufacturer's guidelines for the recommended lubricant and intervals for application. Proper lubrication reduces friction, which can help extend the motor's lifespan. Lastly, examine the motor's mounting and alignment periodically to ensure it is secure and correctly positioned. Loose mounts or misalignment can cause unnecessary stress on the motor, leading to premature failure.

Regular Inspections

Regular inspections are crucial for ensuring the optimal performance of your vehicle's motor. It is recommended to conduct these routine checks at regular intervals to identify any potential issues before they escalate into major problems. During these inspections, pay close attention to any unusual sounds, vibrations, or leaks that may indicate underlying issues with the motor.

Additionally, it is important to inspect the motor's components such as the belts, hoses, and electrical connections for any signs of wear and tear. Checking the fluid levels, including oil and coolant, is also essential to prevent overheating and mechanical failures. By staying proactive with regular inspections, you can prolong the lifespan of your motor and maintain its efficiency for longer durations.

FAQS

What are some common signs of motor failure?

Common signs of motor failure include overheating, strange noises, decreased performance, and an increase in energy consumption.

How can I evaluate a motor's performance?

You can evaluate a motor's performance by checking for any unusual vibrations, inspecting the motor for signs of wear and tear, and monitoring its energy consumption.

What should I do if my motor is experiencing starting difficulties?

If your motor is experiencing starting difficulties, you should first examine the starter motor to ensure all connections are secure and there are no signs of damage.

How can I prevent motor failure through regular maintenance?

You can prevent motor failure through regular maintenance by conducting thorough inspections, cleaning the motor regularly, and ensuring all components are properly lubricated.

When should I schedule regular inspections for my motor?

It is recommended to schedule regular inspections for your motor at least once every six months to catch any potential issues early and prevent major breakdowns.

Related Links

Remote Control DysfunctionWeather Stripping Issues